The simplest possible definition of an ERP system generally would be a program that business leaders use to organize and run the majority of their business.

That’s how I would describe an ERP system today, but they have a long history and different meanings to different businesses.

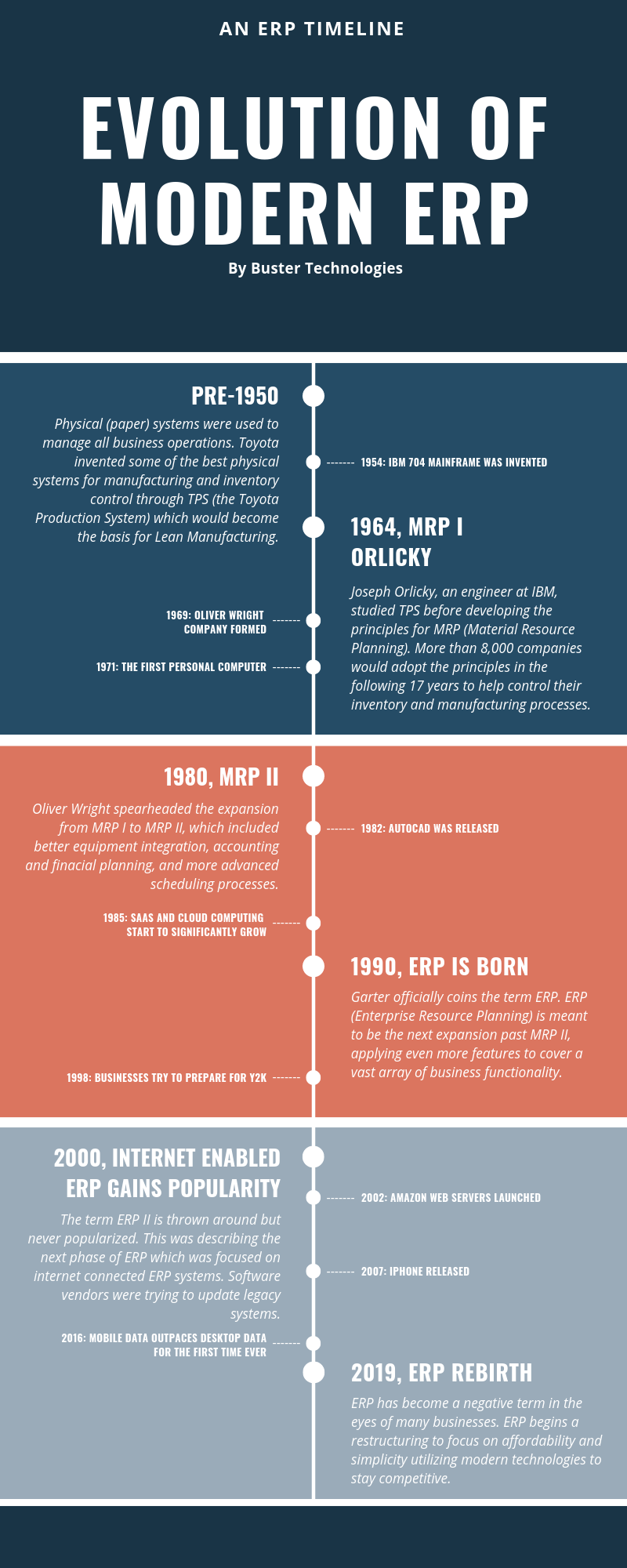

The complete journey of ERP is an interesting story. It was created out of a need when early mainframe computers came into existence and businesses required better organizational tools. At the rise of every major technological innovation, ERP has always been forced to adapt and evolve. Even if a little bit behind the curve, it has done that up to today.

I’m going to explain the evolution of ERP at each of those major points throughout its journey to become what it is today as well as the potential future of these types of systems.

What does ERP mean?

ERP stands for Enterprise Resource Planning. Honestly, this acronym doesn’t 100% make sense for the modern business. ERP can still bring a huge amount of value to businesses, but the term has morphed and evolved from strictly material and resource planning to supporting a massive range of operations for the business.

This would involve functions like accounting, manufacturing, logistics, human resources, budgeting, business intelligence, purchasing, order processing, e-commerce, customer relationship management, time tracking, invoicing/billing, quality assurance/control, or warehouse/inventory management.

ERP is not strictly those functions. An ERP for your business might involve all, some, or none of those functions. It might also involve completely different functions that I didn’t list. ERP today just means a centralized system that runs the majority of your business operations.

What is the point of ERP?

You can read more about the history of ERP below, but generally, ERP systems are meant to be a centralized system for business operations. Instead of having an app for accounting, an app for sales, an app for manufacturing, etc. it’s all built into a single system where data and processes can be intertwined if needed.

It is meant to bring benefits such as:

- Easier maintainability: Worry about maintaining 1 system instead of multiple.

- Data integrity: Company data is controlled from a single location.

- Efficiency: Simplified user training and usability because they access a single system for everything that they need day today.

- Streamlined: Data and processes can link more easily within the same system compared to tying processes together across multiple systems.

Before ERP

To truly understand what ERP represents today, you need to know where it came from. It's origin begins with early manufacturing and warehousing companies that wanted to take advantage of the recent advances in mainframe computing between the 1950s and 1980s.

Manufacturing and MRP I

Manufacturing is really where it all started. The complications of running a manufacturing businesses before computers generated a need for pen and paper processes which could be seen as the foundation for MRP. Toyota developed a framework called TPS (Toyota Production System) which included tools like physical cards attached to parts on an assembly line designating details and instructions for that part.

Before the initial mainframe systems, manufacturing businesses had to track incoming/outgoing logistics for all parts, on-hand inventory in multiple warehouses, the consumption of raw parts into sub assemblies and finished goods, quality assurance, etc. all by hand.

Once computers became (slightly) more available for businesses is when the guidelines for MRP were officially developed by Joseph Orlicky in 1964. Orlicky was an IBM engineer who had heavily studied the TPS and took inspiration from it before developing MRP.

The scope of MRP initially consisted of tracking some essential manufacturing information in computerized systems/applications to allow for users to answer some simple questions:

- Inventory control (what parts do we have?)

- Bill of material processing (what does it take to create a part or finished good?)

- Manufacturing scheduling (how many parts or finished goods can we make? when can we make them?)

- Order scheduling (when do we need to order parts to support the manufacturing schedule?)

- Work instructions (what are the exact instructions for making a certain part or finished good?)

These original MRP systems were implemented on early mainframe computers like the IBM 360 which was larger than a refrigerator. MRP serves as the father of modern ERP.

The Creation of MRP II

MRP II came from the need for expanding MRP. 15-20 years after the creation of MRP, computer systems had dramatically evolved. Mainframes were no longer the only option for businesses. Personal computing had come around, leading to the mass production of computers making it cheaper and easier for businesses to begin implementation.

Client server architectures and micro computing started to make more sense for businesses, so as MRP vendors were forced to evolve for the first time from their original mainframe software, MRP II guidelines were created to explain the new functionality that comes with that evolution.

MRP II focused on the limitations and issues not yet solved by MRP. This consisted of:

- Machine and equipment integration

- Accounting and financial planning

- More advanced scheduling and forecasting

- Capacity planning

- Quality assurance

The Birth of ERP

Software vendors continued to work and build up these now 25-30 year old applications. Some vendors were working with thousands of customers and added functionality to handle more and more use cases that were consistently falling outside of the scope of MRP II.

The term ERP was officially coined by Garter in 1990 to describe this next phase. They felt that the software systems were expanding so far past just material planning that they needed a new term to describe them. They were beginning to focus on business functions obviously outside of responsibility of the warehouses and manufacturing facilities.

ERP was the beginning of a software system that covers essentially any business function that a business needs to run. This led to the enterprise MRP providers of the time, like SAP for example, to start updating their now legacy software.

The major benefit of ERP at the time was having a monolithic application on-site for the company. Instead of managing a collection of decoupled, individual programs, maintainers could worry about a single app that handles the majority of the work for the company. This was huge for companies at the time.

Internet and SAAS

At the same time that ERP was on the rise, so was the growth of the internet and early SAAS (software as a service) applications.

SAAS was trying to be the opposite of what ERP wanted at the time. While ERP was focused on becoming a monolithic, everything you need with a bow on top, type of system installed on-site in your facility, SAAS companies wanted to handle the infrastructure for you.

Most Software developers and many business owners today do not think about this issue any more. There are some scenarios where a company would buy all of the equipment, configure a rack a servers on-site, hire internal or external IT to manage the servers, and deploy a business application on it. But most of us look to the cloud for server management these days.

That's exactly what SAAS companies were driving towards.

And the idea took off pretty quickly because companies liked the idea of reducing all of this overhead. Managing servers is not a simple process and if a SAAS company can do it more efficiently and cheaper then it's going to be a win-win.

While the internet and SAAS companies were building out these infrastructures, ERP was getting pulled around in multiple directions because of the rise of these new technologies. The ERP companies were trying to update their legacy mainframe software to run as client server applications. At the same time, they had to begin thinking about and planning for creating internet-enabled applications. And finally now they are faced with the on-site vs off-site question.

Even up to today, major ERP companies are still slowly migrating their applications to work both on-site and as an off-site SAAS application.

The Mobile Revolution

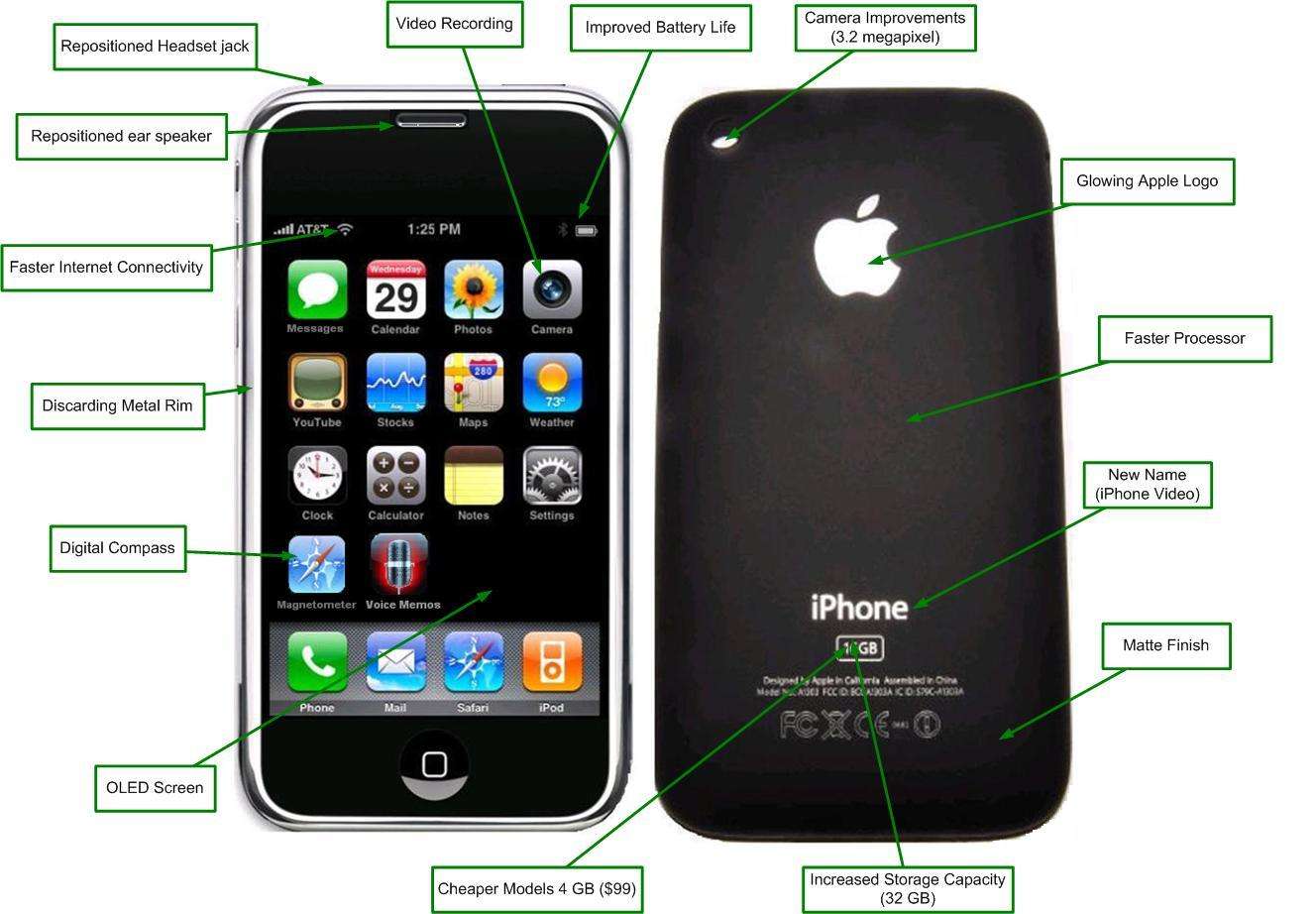

Another rise of a new technology forced ERP vendors to again adapt. One of the biggest releases was the 2007 release of the iPhone from Apple. At this point, ERP vendors are still in the process of migrating their systems towards a SAAS or cloud computing model.

While simultaneously doing that, the entire software world starts thinking about how mobile devices are going to affect their application development. Eventually in 2016, mobile data for the first time outpaces all desktop data and is just another indicator that ERP vendors and all software vendors have ensured their applications are mobile ready.

What's Next?

Now we are in 2019 and most ERP vendors are still in the process of catching up to SAAS and cloud computing applications.

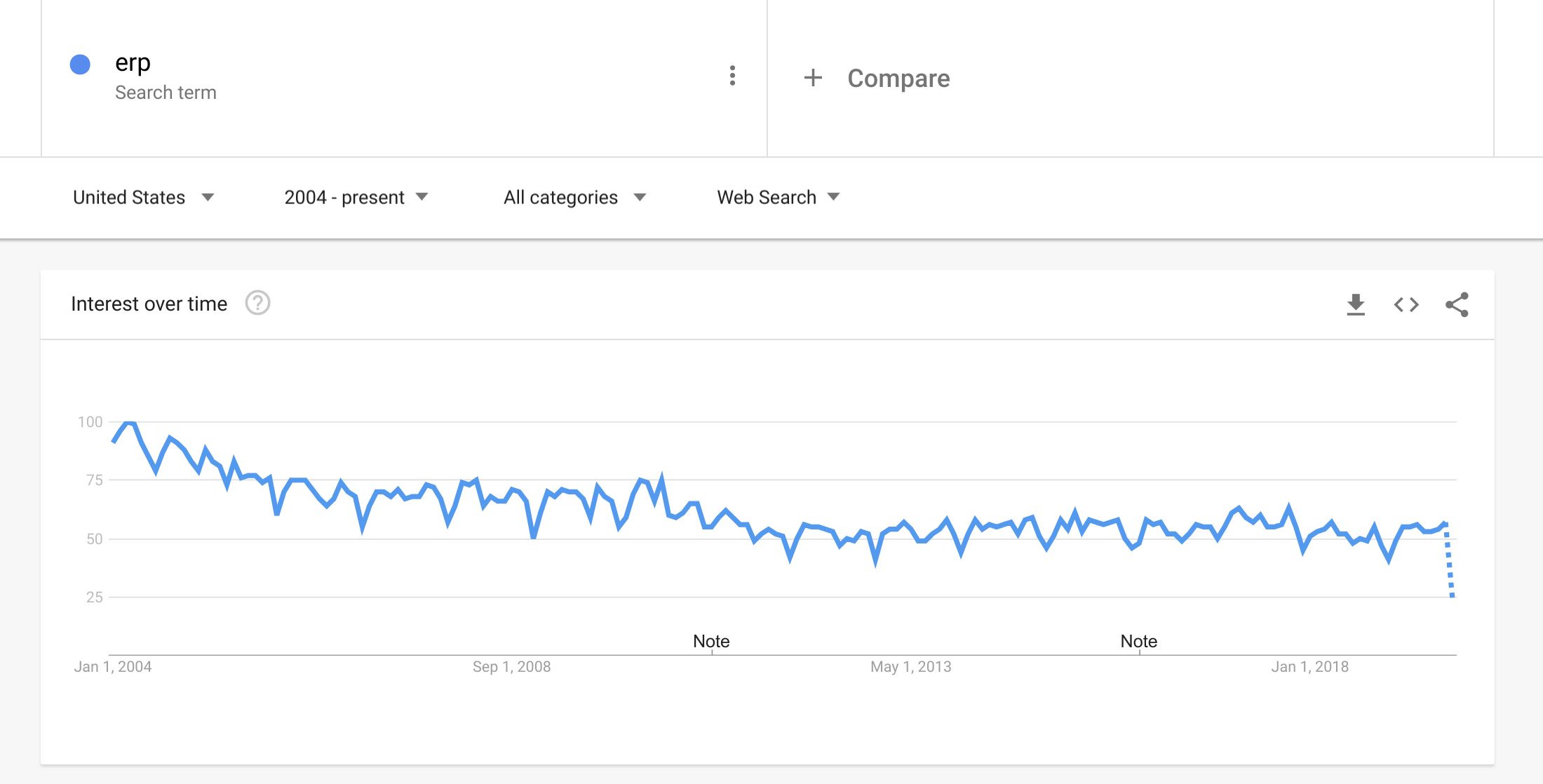

Unfortunately, the term ERP has been slowly trending downward for the last 15 years. The rise of more and more SAAS applications to handle very specific business needs has become the go to tool for most businesses.

Some ERP businesses are trying to ignore the stigma associated with the term by re-branding as a "suite of business apps" or a "business management application", but the overarching issues come down to the pricing models and idea of modular vs. monolithic.

ERP needs a rebirth again and adapt just as it has in the past, to move away from pricing that only the elite companies can afford. Even when a vendor offers cheaper license fees, companies still pay $50k-$100k on average when doing an ERP implementation because of support costs, training, customization fees, configuration, hosting, maintenance and upgrades. All inclusive costs for ERP will provide a more inclusive option for small to medium sized businesses.

We also need to move away from building it all in house. There's still a place for a home base/single source of truth application like a great ERP, but the ERP system does not need to be entirely responsible for providing all of that functionality. It can play nice and integrate with other applications out there.

I believe that's the next phase of ERP, if the term ERP is even going to stick around.

Thanks For Reading

I appreciate you taking the time to read any of my articles. I hope it has helped you out in some way. If you're looking for more ramblings, take a look at theentire catalog of articles I've written. Give me a follow on Twitter or Github to see what else I've got going on. Feel free to reach out if you want to talk!